Hydro Dipping Without Activator: What Really Works

Hydro dip Without Activators play a crucial role as chemicals that liquefy the ink on hydro dipping films made from polyvinyl alcohol. Your item won’t get proper adhesion without enough activator. Too much activator can mess up the ink’s dispersion. Many crafters search for alternatives because of this tricky balance.

The hydro dipping work welcomes new breakthroughs. Laser hydro dipping film lets you dip items Without Activator spray. This technology makes hydro dipping more affordable and available to DIY enthusiasts.

This piece explores quick ways to hydro dip without traditional activators. You’ll learn why crafters use activators and which alternatives actually work. Some materials like ABS plastic accept hydro dipping film without any paint prep. We’ll show you homemade Without Activatorformulas and techniques to hydro dip without spray paint.

Why Activators Are Usually Needed

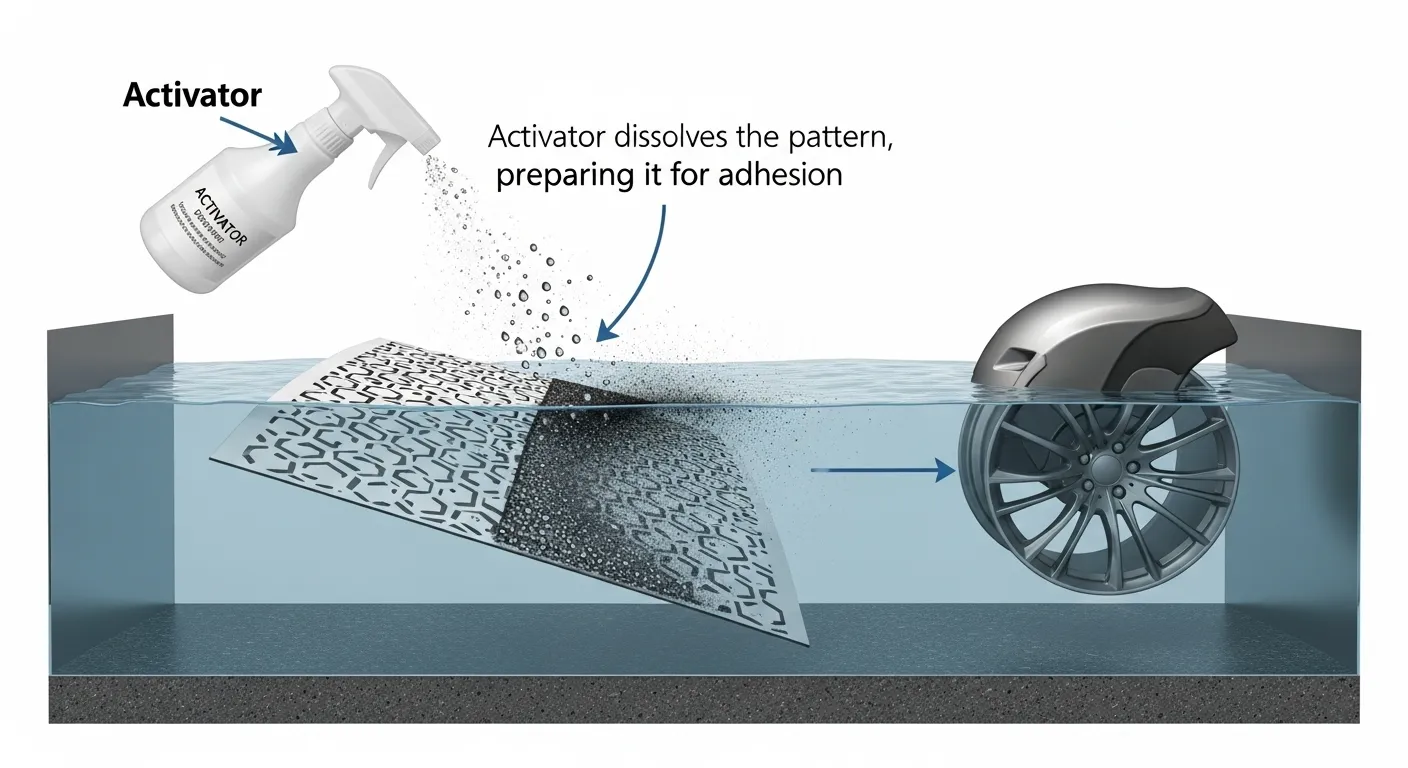

A hydro dipping process’s success depends on one vital component – the Without Activator This specialized chemical solution plays a fundamental role. It liquefies the ink on hydro dip films and ensures proper dissolution when placed on water.

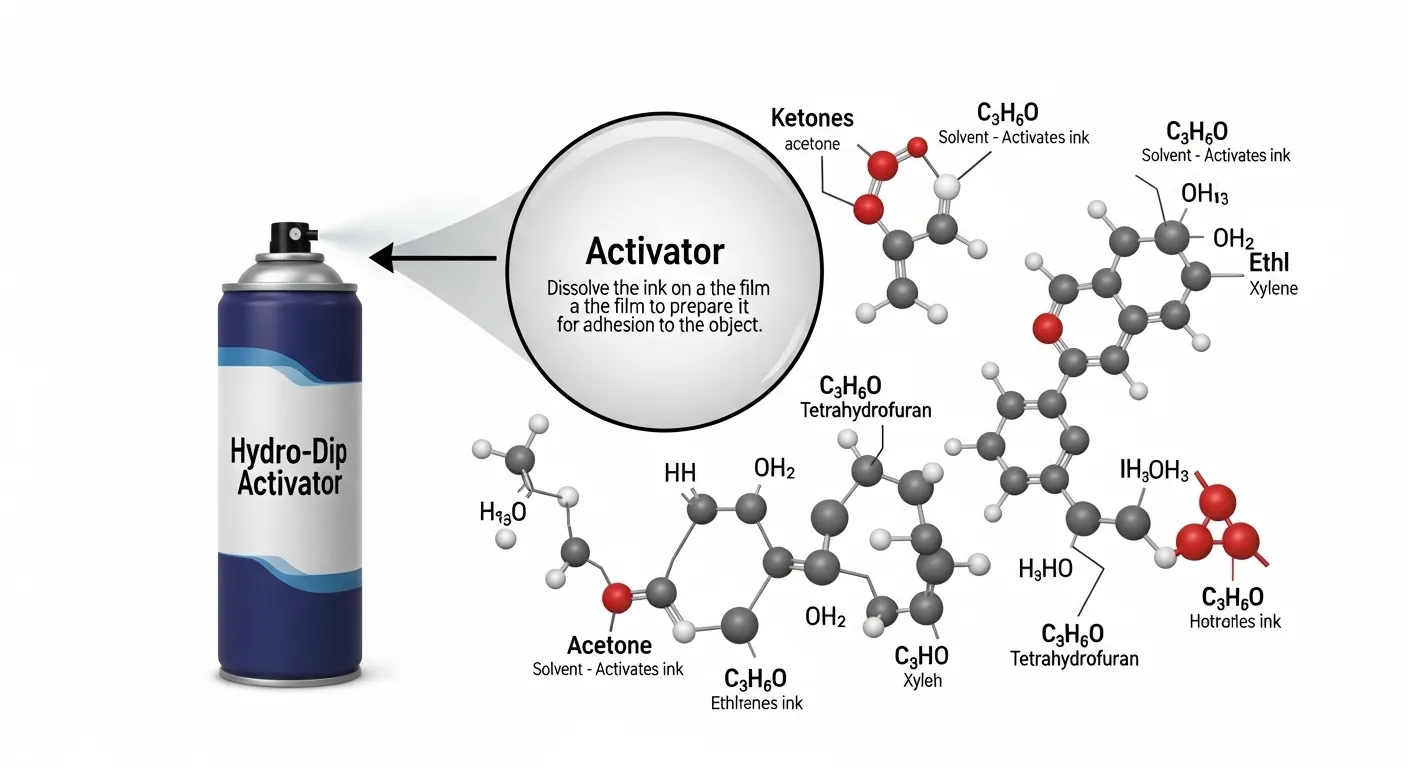

What the Activator Is Made Of

The hydro dip activator consists of a colorless, low-viscosity liquid that dissolves water-soluble PVA (polyvinyl alcohol) film. Commercial formulations combine potent solvents like xylene, isobutanol, butyl, and acetone. These ingredients break down the film and preserve the printed design’s integrity.

How the Activator Works

The activator’s technical function works with precision. It dissolves the film’s binding agents while keeping the ink pattern intact. This creates a floating ink layer that sticks to objects during immersion. The right activation improves pattern clarity and vividness, and boosts surface adhesion.

Finding the Right Balance

Proper balance in activator application is significant. The film won’t stick to your item or fully liquefy with insufficient Without Activator. Too much activator causes incorrect ink dispersion and poor adhesion. This delicate balance makes activator application one of the most technically demanding parts of successful hydro dipping.

Exploring Alternatives and Innovations

These challenges aside, understanding Without Activator chemistry creates opportunities to learn about alternatives or modify traditional processes.

Alternatives That Actually Work

Several proven alternatives exist in the hydro dipping world to bypass traditional activators.

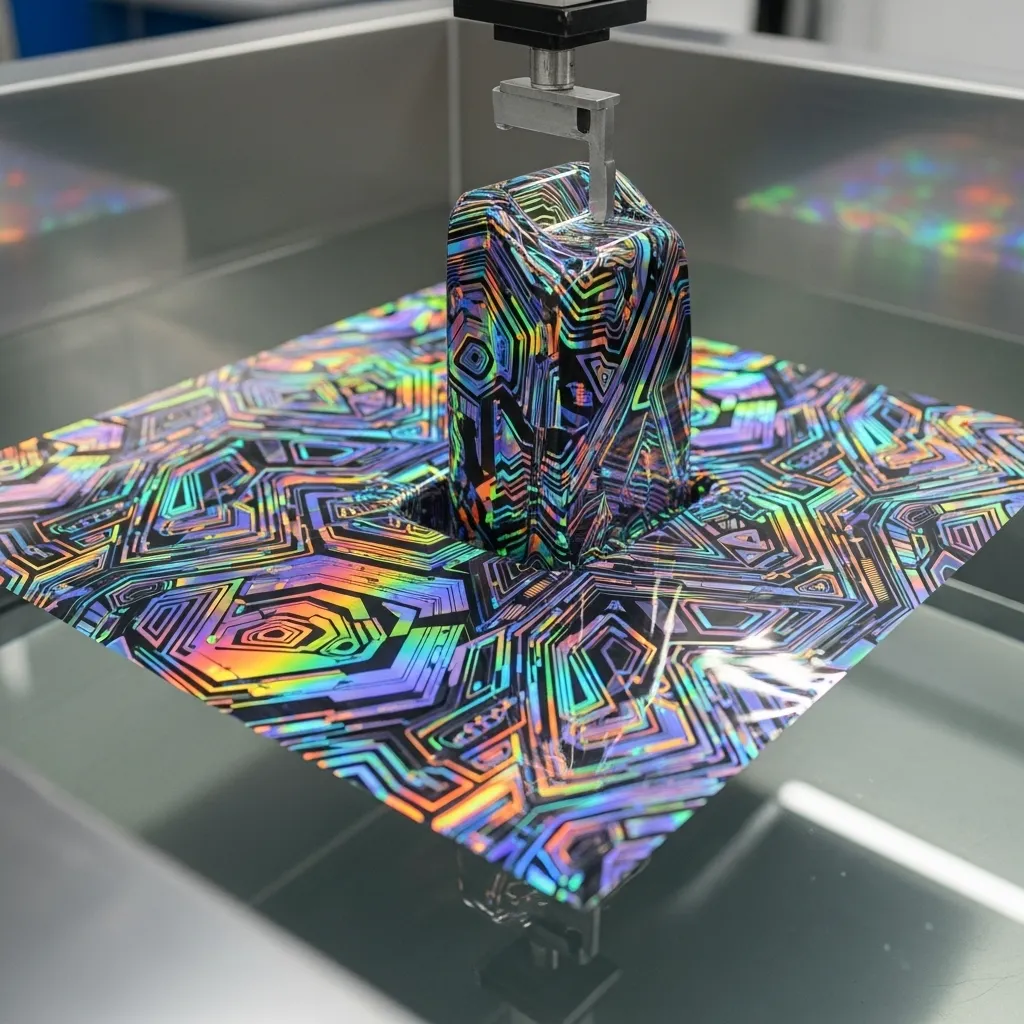

Laser Hydro Dipping Film

Laser Hydro Dipping Film has become a game-changing option that eliminates the need for activator sprays. This technology cuts overall costs and makes the process simpler, which makes it perfect for beginners.

Clear Intercoat

Clear Intercoat is a solid alternative. This transparent basecoat lets you dip parts directly while keeping their original color. You just need to scuff the surface, apply the intercoat, and dip. The product works on many materials and creates a chemical bond with both the film and clear coat.

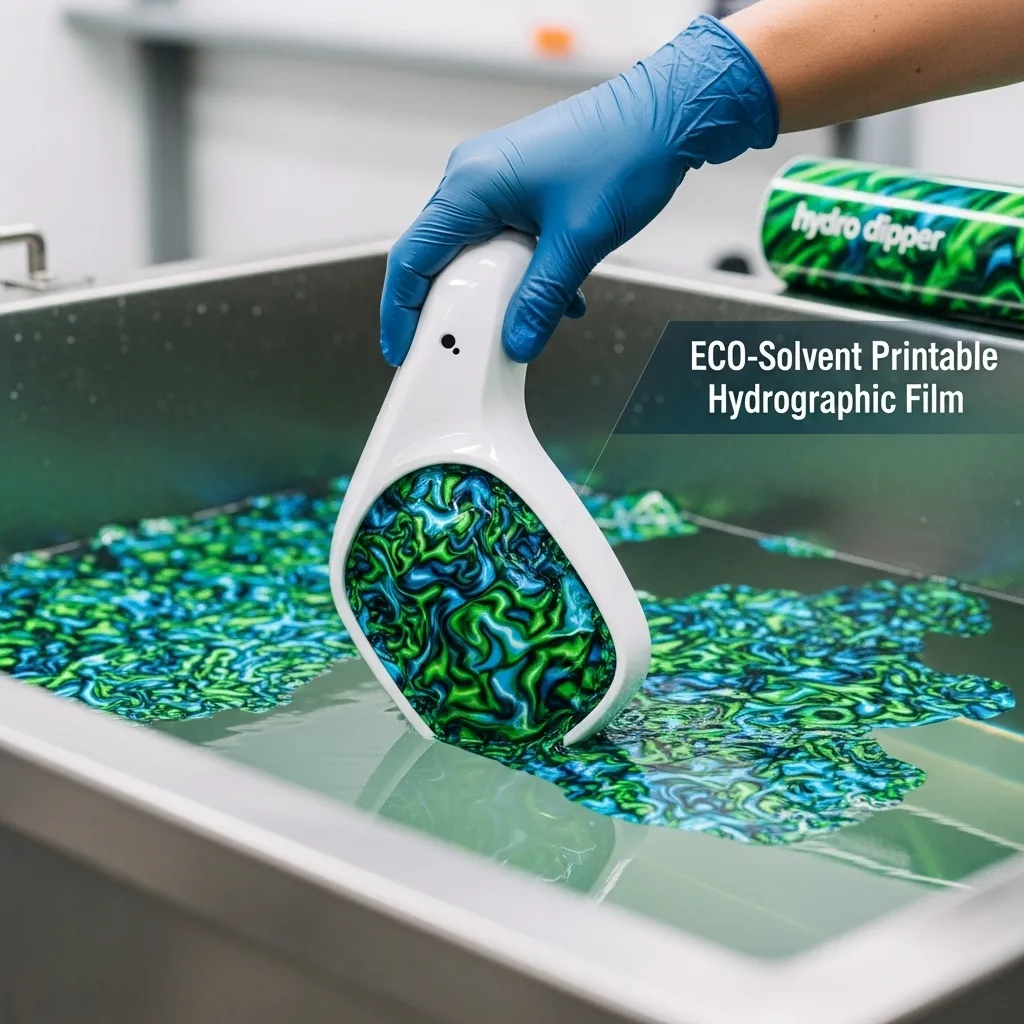

ECO-Solvent Printable Hydrographic Film

ECO-Solvent Printable Hydrographic Film gives you customization options without traditional Without Activator. This specialized film allows you to print custom designs using ECO-solvent ink printers. The film works like standard hydrographic film after printing but needs special “Activator B” instead of conventional activators.

Acrylic Paint Method

Acrylic Paint Method is available to people who don’t have spray paint. This technique uses regular craft supplies instead of specialized chemicals.

Material Compatibility

Some materials take hydro dipping better than others. ABS plastic accepts hydro dipping film directly without paint. Materials like chrome, raw aluminum, and glass resist proper adhesion whatever method you use.

What Doesn’t Work (And Why)

DIY enthusiasts often try to save money by using substitutes instead of proper hydro dip Without Activator. These alternatives usually create disappointing results. How to Choose the Right Hydro Dipping Tank Size is good guiding.

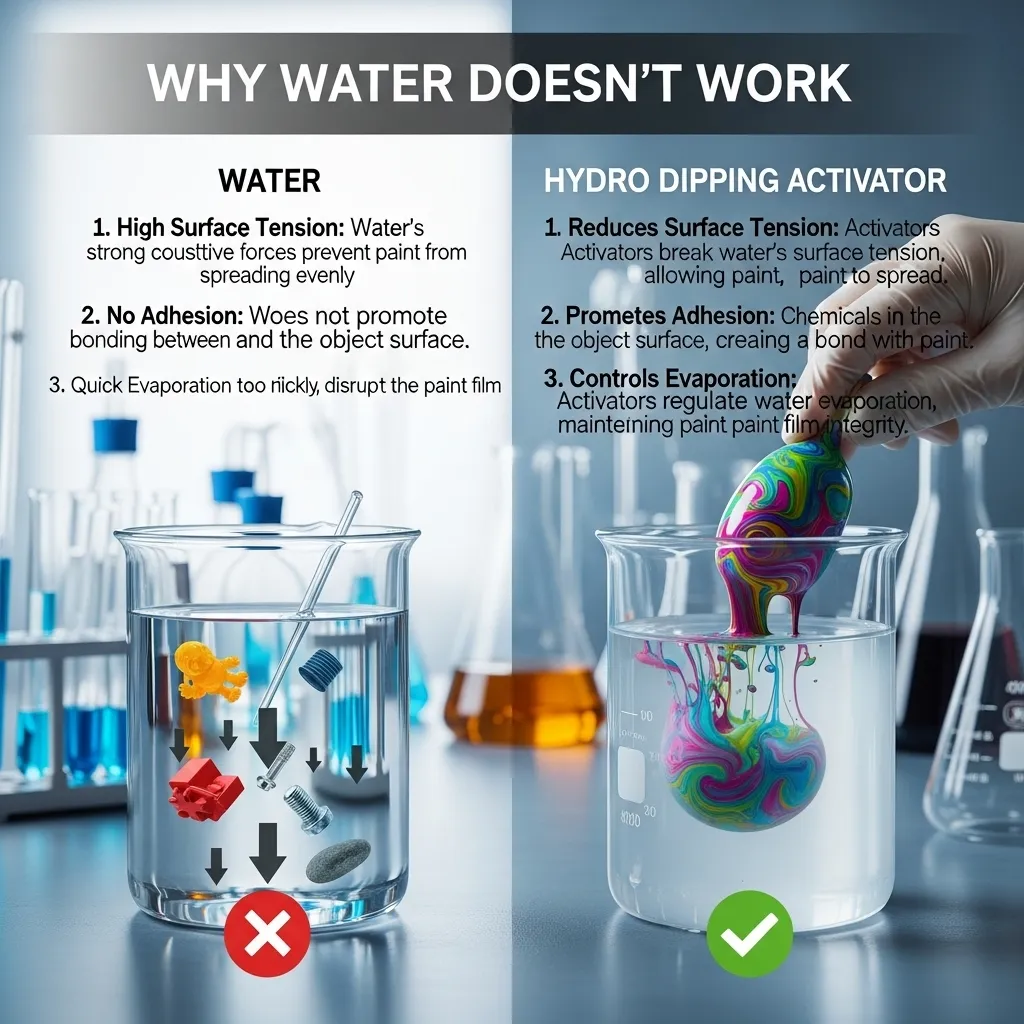

Why Water Doesn’t Work

You can’t just use water as an activator. It doesn’t have the chemical properties to dissolve the PVA film correctly. The design stays stuck on the water’s surface or won’t stick to your project.

The Problem with Hairspray

People online suggest hairspray a lot, but it doesn’t work. Hairspray lacks the right solvents like acetone or xylene that break down the hydro dip film. You’ll end up with a messy, half-dissolved film and poor pattern transfer.

Rubbing Alcohol Isn’t Strong Enough

Rubbing alcohol is another common substitute that doesn’t deliver. While it has some solvent properties, it’s too weak to activate the film properly and leaves uneven patterns.

Why Vinegar Fails

Vinegar’s acidic properties are different from the solvent action you need. Yes, it is harsh enough to ruin your pattern completely.

WD-40 Creates Adhesion Problems

WD-40 looks like a good option because of its petroleum base. The problem is that it leaves an oily film that stops the pattern from sticking to your project.

Nail Polish Remover Doesn’t Work Either

We tried nail polish remover, even the acetone-based ones. These products are too diluted to dissolve the film well and miss other important ingredients found in commercial activators.

Conclusion

DIYers and professionals face unique challenges when hydro dipping without activator. Traditional activators are vital for PVA films due to their chemical precision. However, new alternatives like laser hydro dipping now eliminate chemical activators and lower costs.

Clear intercoat and ECO-solvent printable films also offer practical options. Material choice greatly affects results, ABS plastic works well without primer, while chrome, raw aluminum, and glass resist adhesion. Also you can read our comparison guide about How to Hydro Dip Like a Pro also.

Avoid wasting time on ineffective substitutes like water, hairspray, or vinegar. These DIY “hacks” fail because they lack the chemistry to dissolve the film or set patterns properly.

Modern technologies now make hydro dipping easier and more accessible. Your project type, budget, and materials decide whether activator-free or traditional methods work best. Understanding the chemistry and choosing the right process ensures successful hydro dipping.