Hydro Dipping Machine: Fully Automatic & High-Performance

For businesses in automotive customization, industrial finishing, and professional water transfer printing, a reliable hydro dipping machine is essential. The fully automatic hydro dip machine is engineered to deliver precision, efficiency, and consistent results for rims, accessories, and other hydrographic-ready components.

Designed for mid-scale production, it minimizes manual labor and maximizes throughput, making it ideal for workshops and small factories.

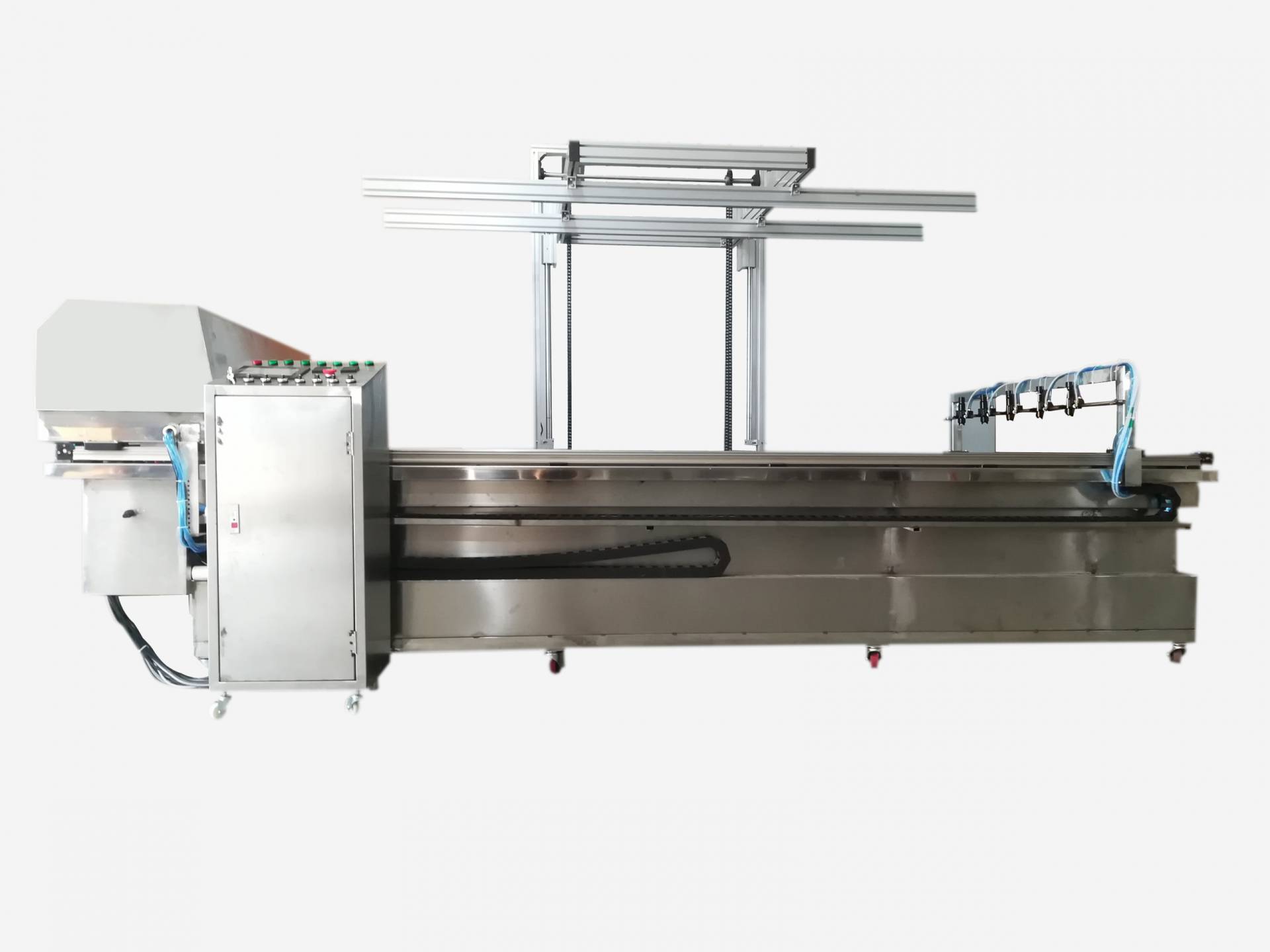

Overview of the Hydro Dipping Machine

This industrial hydro dipping machine is a state-of-the-art solution for professional hydrographic operations. With a fully automated system, it handles film feeding, activator spraying, and robotic product dipping with minimal operator input. Continuous water circulation and precise temperature control ensure smooth, even coatings for every item. Built from robust stainless steel and equipped with high-capacity servo motors and heating elements, the machine combines durability with efficiency.

The system is versatile, accommodating a wide range of rims, automotive parts, and small industrial components. Its automated design reduces labor costs, prevents film waste, and ensures consistent, professional results for every production run.

Technical Specifications

The technical features of this hydro dipping machine are designed for performance and reliability:

| Specification | Details |

|---|---|

| Machine Mode | 3M Fully Automatic Hydro Dip Machine |

| Dipping Area | 200 × 110 × 70 cm |

| Material | 2.5 mm ± 0.2 mm 201# Stainless Steel |

| Heating Elements | 208–240V, Single Phase, 6000W |

| Automatic Spray System | 130 × 35.2 spray guns; servo motors 400–750W |

| Water Cycle System | 220V, 750W pump with filtration |

| Certification | CE |

Dual Operation Modes

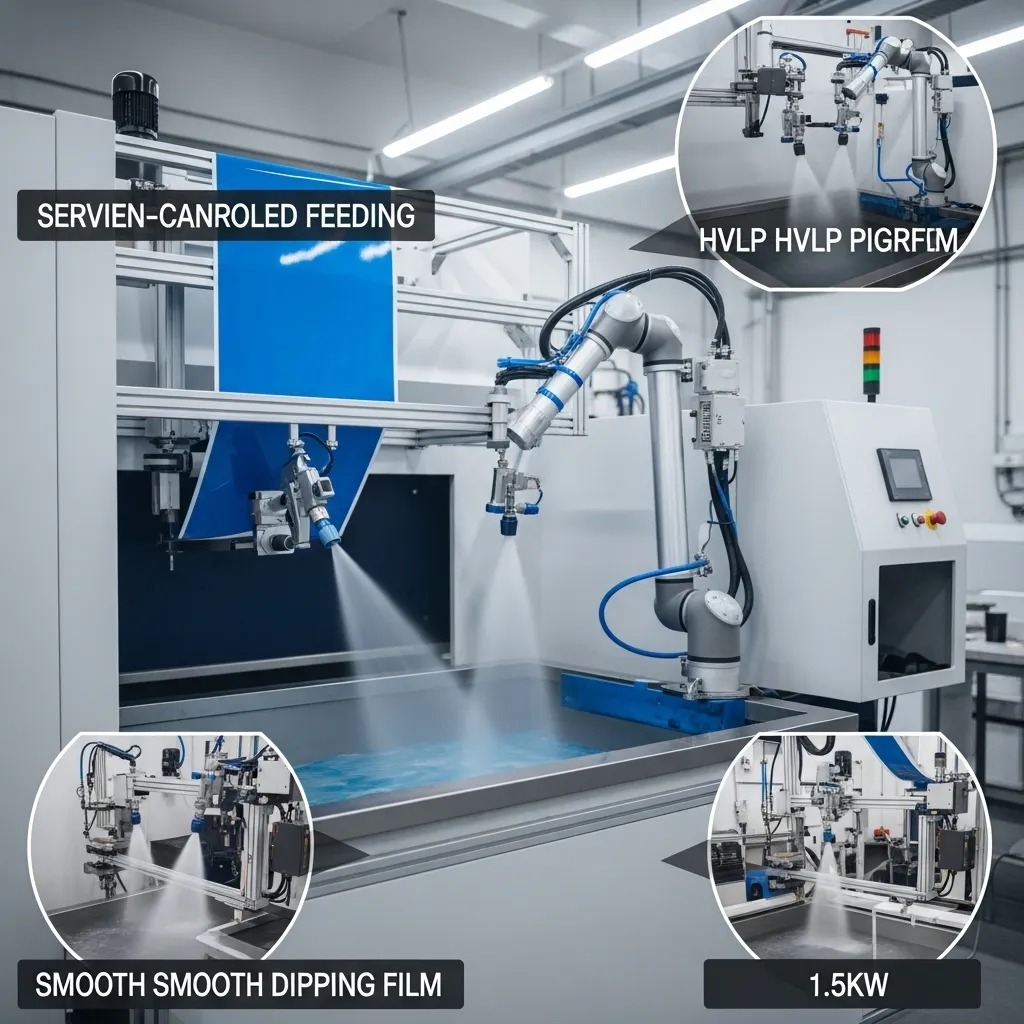

The machine offers fully automatic and manual operation modes to suit different production needs. In fully automatic mode, the machine handles film feeding, activator spraying, dipping, and water circulation with the push of a button. This ensures consistency and speed for high-volume operations.

Manual mode allows independent control of each system, ideal for testing, maintenance, or fine-tuning specific parts. Operators can precisely adjust dipping angles, film length, and speed using the integrated PLC panel.

Key Features and Benefits

The hydro dipping machine excels in both efficiency and performance. Its servo-controlled film feeding system ensures accurate placement, reducing film waste. Dual HVLP spray guns evenly activate the film for a flawless transfer. The 1.5kW servo robotic arm provides stable, repeatable dipping, while two 6000W heating elements maintain optimal water temperature. Continuous water filtration keeps the tank clean, reducing preparation time and water usage.

With these features, operators enjoy reduced labor, consistent results, and faster production cycles, making it ideal for industrial hydro dipping applications.

Performance and Reliability

Designed for professional use, this machine completes a full dipping cycle in just 3 minutes, combining speed with precision. Its robust construction, including stainless steel panels and high-quality motors, ensures long-term reliability. Compatible with a variety of hydrographic films and substrates, it delivers smooth, uniform coatings on rims, automotive parts, and other components.

Hydro Dipping Machine Applications

This machine is perfect for:

| Application | Ideal Use |

|---|---|

| Automotive Rims | Professional hydrographic finishing for alloy and steel rims |

| Automotive Components | Door handles, trims, and accessories |

| Consumer Products | Cases, gadgets, and decorative parts |

| Industrial Parts | Custom components requiring consistent coating |

Why Choose This Hydro Dipping Machine

Investing in this fully automatic hydro dip machine means gaining a reliable, high-performance solution for professional hydrographic operations. Its automation reduces labor, while the servo-controlled systems ensure precision. Continuous water filtration and adjustable heating save time, reduce waste, and maintain a clean work environment. CE-certified for safety and built with durable stainless steel, this machine is ideal for workshops, small factories, and hydrographic studios aiming for consistent, high-quality finishes.