Trending Hydro Dipping Patterns 2025: Top Designs & Applications

Hydro dipping, also known as water transfer printing, applies printed PVA film onto three-dimensional surfaces for decorative finishes. In 2025, this technique sees evolution towards greater pattern complexity, sustainability, and automation. This article explores trending hydro dipping patterns, their significance, and provides practical guidance for hobbyists and small businesses. Readers will find trend analysis, supply checklists, expert tips, sourcing guidance, eco-friendly innovations, application examples, and a market outlook. Key phrases like “hydro dipping patterns 2025,” “chrome carbon hydro dip,” “E3D camouflage hydro dipping,” and “eco friendly hydrographic films” are integrated to empower immediate action.

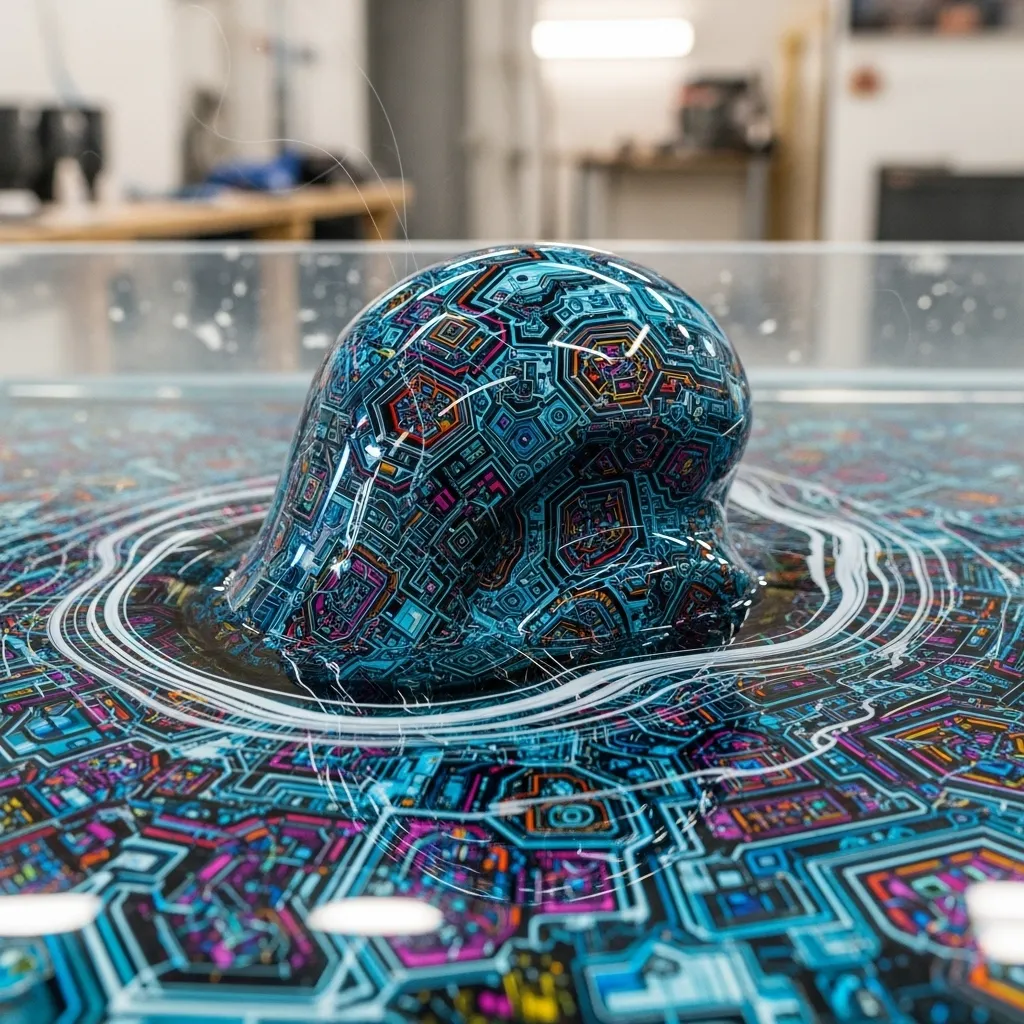

Popular Hydro Dipping Patterns in 2025

The popular hydro dipping patterns of 2025 balance functional demand with visual novelty, combining tactical utility, hyper-realistic textures, and expressive abstract art. Durable, high-fidelity prints like chrome carbon fiber effects offer a sleek, modern look, while realistic wood and marble textures provide an authentic, luxurious feel. E3D-inspired tactical geometries appeal to outdoor enthusiasts and those appreciating a rugged aesthetic. Modern abstract designs and small-batch specialty films fuel desire for unique, limited-run items across electronics, fashion, and home décor. These leading categories are broken down below, discussing their practical uses and appeal.

Top pattern categories for 2025 include tactical camouflage variants for high-performance gear, chrome carbon and realistic texture films mimicking premium materials, modern abstract and painterly motifs for consumer goods, and niche novelty prints for collectors. Each category suits specific substrate types and finishing requirements, informing pattern and process choices. Their versatility, aesthetic appeal, and ability to meet evolving consumer demands drive their strong resonance this year.

Military & Tactical Patterns

In 2025, military and tactical camouflage Hydro Dipping Patterns are heavily influenced by E3D-style geometry and blended tactical variants, balancing concealment and visual depth. Layered masking within the film design maintains scale fidelity on complex curved surfaces like rifle stocks and helmets. These Hydro Dipping Patterns are typically finished with abrasion-resistant top coats for longevity.

Substrate compatibility includes polymers, metals, and fiberglass, requiring appropriate adhesion promoters and primers. High-durability clear coats are crucial for performance under harsh conditions. Practical tips include matching pattern scale to the object size and testing on small samples. Trends are driven by functional buyers and those appreciating rugged aesthetics, leading to increased supply of intricate geometric micro-Hydro Dipping Patterns. Using substrate-specific adhesion promoters and suitable film repeat sizes reduces waste and ensures intended performance.

Carbon Fiber & Realistic Textures

Chrome carbon fiber effects and realistic texture films (wood grain, marble, metallic stone) are reshaping hydrographics by offering premium visual fidelity at a lower cost than real materials. They are popular for automotive customization, consumer electronics, and interior accents. Success relies on high-resolution printing and precise activation to maintain weave continuity and reflective highlights.

Meticulous surface preparation, primer selection, and multi-stage clear coats are critical for emulating depth and realism.

Chrome carbon provides aesthetic value, not structural strength. Use-cases include dashboard trims, wheel accents, and phone cases, where perceived value increases with convincing texture and gloss.

Pair chrome carbon films with semi-gloss to high-gloss clear coats. Monitor activation and dipping speed to prevent pattern distortion on complex curves.

Modern Abstract Designs

Modern abstract and painterly hydro dipping designs are surging in popularity for personalized small electronics, fashion accessories, and interior accents. These prints feature on-trend color palettes, gradient fades, and layered translucency, ideal for limited-run products and artist collaborations. Techniques include multi-pass dipping, selective masking, and localized clear-coat variations for depth and texture.

Applications span laptop shells, fashion hardware, and bespoke home décor, prioritizing visual impact over extreme durability. Designers favor films supporting intricate color layering and multi-stage activations, enabling complex designs with crisp edges for small production runs.

Niche & Specialty Patterns

Niche and specialty Hydro Dipping Patterns like skulls, flames, flags, gamer motifs, and limited-edition artworks remain strong in 2025, driven by collector markets and bespoke brand collaborations. Small-batch film runs and custom-printed PVA sheets cater to specific verticals like gaming peripherals and custom firearms accessories, where exclusivity enhances perceived value.

Sourcing limited-run films often requires direct engagement with manufacturers for artwork rights and precise color matching. Production shops need meticulous sample archives and rigorous quality checks. Anticipate differences in inventory management and longer lead times for bespoke prints.

Achieving Trending Hydro Dipping Patterns

Reproducing trending hydro dipping patterns in 2025 demands precise supplies, disciplined surface preparation, accurate activation, and meticulous finishing. Key decisions include choosing appropriate base coats, correct film types, controlling water temperature and activator application, and matching clear coats to expected wear. This section covers essential supplies, step-by-step actions, and advanced technique pointers.

Essential supplies are foundational. While beginner kits offer a basic setup, professional configurations involve specialized equipment. Focus on high-quality adhesion promoters, activators (low-VOC or standard), and premium clear coats. The next subsection details recommended specifications.

Essential Supplies

Successfully applying trending hydro dipping patterns requires high-quality hydrographic films, compatible base coats and primers, activators (standard and low-VOC), abrasion-resistant clear coats, and an appropriately sized dipping tank. Hobbyists start with compact tanks and basic kits. Professionals invest in larger tanks, automated film feeders, and low-VOC activators for efficiency and compliance.

Key specifications: Film resolution and opacity (high-resolution for intricate details, opaque for vibrant Hydro Dipping Patterns). Activator VOC level and reactivity (low-VOC for regulated spaces, standard for faster activation). Base coats and primers for adhesion and color.

Step-by-Step Process

A reliable step-by-step process minimizes errors and improves repeatability: surface preparation, priming, film placement, activation, dipping, rinsing, drying, and clear coating. Proper surface preparation (cleaning, sanding, priming) ensures optimal adhesion. Activation must be uniform and timed to film chemistry, with precise water temperature control. Consistent dipping speed and angle prevent pattern distortion.

After dipping, rinse with low-pressure water to remove PVA film. Thorough drying is essential before applying a clear coat matched to the item’s intended use and durability. This systematic approach addresses common quality issues and achieves professional results.

Advanced Techniques

To elevate trending hydro dip patterns, employ advanced techniques. Multi-pass layering creates depth, combining translucent films or partial clear coats. Precision masking allows selective pattern exposure and crisp edges. For E3D-style tactical geometries, alignment strategies using registration marks and specialized jigs maintain pattern continuity on complex curves.

Avoid common mistakes like over-activating (pattern distortion) or under-priming (poor adhesion) by testing activation times and adhesion on scrap pieces. Cure clear coats under manufacturer-recommended conditions to maximize hardness.

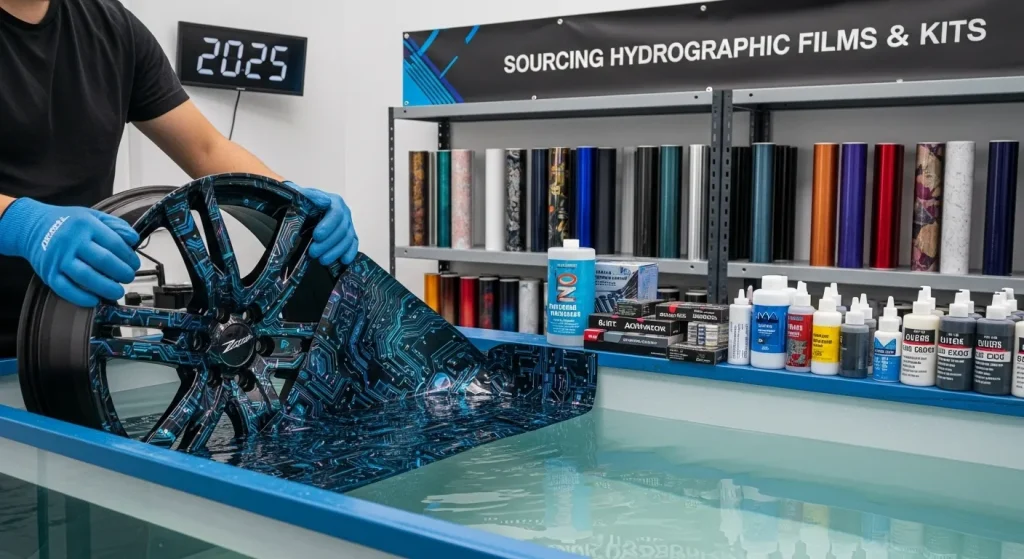

Sourcing Hydrographic Films & Kits for 2025

Sourcing the right hydrographic films and kits is critical, matching pattern fidelity, film construction, and chemical compatibility to project goals. Reputable suppliers provide detailed specifications on film repeat sizes, opacity, and activation requirements. Starter kits offer beginners a compact tank, basic activator, primer, and clear coat. Professional packages feature larger tanks, automation-ready accessories, and higher-grade, often low-VOC, chemical supplies.

Evaluate vendors by reviewing sample photos, technical specification sheets, and inquiring about training/support. Industry leaders like Accio, TWN Industries, Kansas Hydrographics, TSAUTOP, Liquid Concepts, and IKONICS are known for innovation and quality. Consider film scale, opacity, and desired finish. Chrome carbon offers medium-high durability for automotive accents. Wood grain/marble provide medium durability for interiors. Tactical camouflage (E3D) offers high durability for outdoor gear. Abstract/artistic prints have variable durability for electronics/fashion. Test on samples before large production runs.

Choosing Films

Choosing the right film starts with matching pattern scale and opacity to the object size. Large Hydro Dipping Patterns suit expansive surfaces; intricate micro-weave carbon films excel on smaller trims. Film opacity determines base coat necessity. Film thickness and PVA formulation influence handling and activation sensitivity. Consult manufacturer specifications for water temperatures and activator types.

For regulated areas, consider eco-friendly attributes like low-VOC activators. Conduct test dips on representative substrates to validate color rendition and pattern behavior. Communicate with suppliers about substrate chemistry and final use case to prevent costly surprises.

Kits: Beginner to Pro

The best hydro dipping kits in 2025 vary by user experience. Beginners need compact, safe starter kits with clear instructions and smaller tanks. Intermediate kits offer larger tanks, multiple film samples, activator options, and better nozzles. Professionals require kits supporting higher throughput and compliance, including full-sized tanks, automation-ready accessories, and high-grade, often low-VOC, chemical supplies.

Look for comprehensive documentation, sample film sheets, and vendor training/community resources. Choose a kit aligning with project scale and product lifespan, planning clear-coating upgrades as durability demands increase. Prioritize suppliers offering technical support and sample prints for testing compatibility.

Professional Services & Training

When evaluating professional hydro dipping service providers and training programs, focus on portfolio quality, technical depth, and training formats. Look for extensive before-and-after galleries, clear explanations of substrate preparation, and reliable follow-up support. Request references or sample projects mirroring your application for insight into real-world performance.

Effective training covers theoretical knowledge and practical application, including film chemistry, activator selection, masking, alignment, and curing. Consider manufacturers or distributors offering certified training or technical bulletins to reduce the learning curve and ensure current, effective methods.

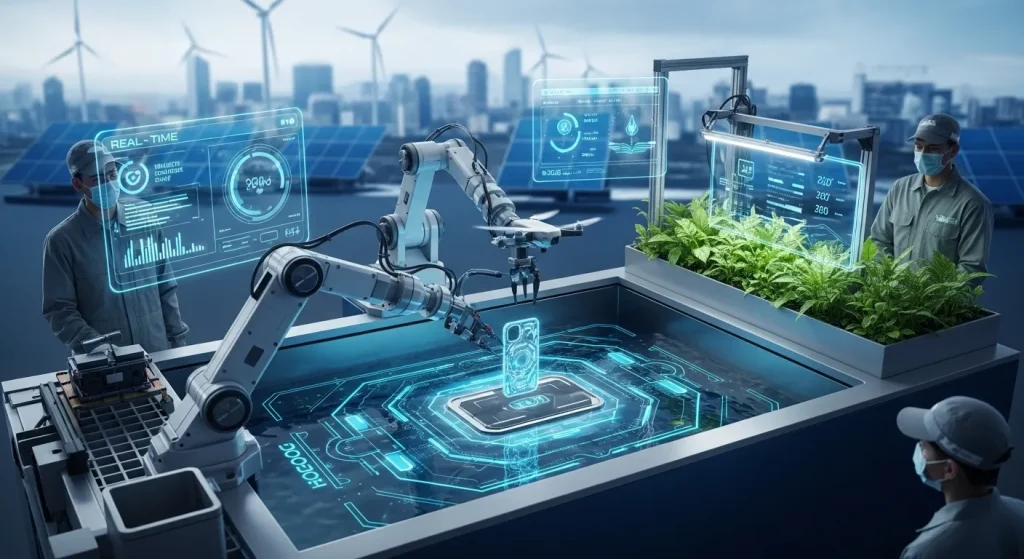

Eco-Friendly & Tech Innovations in Hydro Dipping 2025

Eco-friendly materials and technological advancements are central to Hydro Dipping Patterns in 2025, driven by regulatory pressure and consumer demand for sustainable, lower-VOC solutions and repeatable, automated processes. Low-VOC activators and biodegradable PVA options reduce environmental impact and workplace hazards, though they may require modified activation techniques. Technological improvements like AI-assisted pattern mapping, advanced tank automation, and higher-fidelity printing enhance repeatability and reduce waste, making complex hydro dipping patterns viable for small-batch production. Buyers increasingly weigh sustainability certifications and automation support when selecting films and equipment.

Eco-Friendly Films & Activators

Eco-friendly hydrographic films and low-VOC activators are changing the market by lowering emissions and reducing worker exposure to harmful chemicals, addressing regulations and consumer expectations. Adopting greener options may require modified activation techniques and stricter temperature control. Biodegradable PVA films are sensitive to humidity and storage, necessitating tighter inventory management.

While cost and availability can be factors, shops embracing sustainable solutions gain marketing advantages and reduce compliance risk. Practical tips include side-by-side testing of activation windows and clear-coat adhesion, and coordinating with suppliers for detailed technical data sheets to optimize process parameters for eco-friendly options.

Tech Advancements

Technological advancements significantly influence hydro dipping patterns, enhancing fidelity and consistency. AI-assisted pattern mapping predicts print distortion on complex geometries, allowing precise adjustments. Automated dipping systems improve consistency by controlling motion, minimizing human error. Novel film printing techniques expand possibilities, enhancing color gamut and gradient control for photorealistic textures.

Desktop-friendly alignment tools are increasing for hobbyists. Professional shops benefit from automation, reducing labor costs and improving throughput. These technologies lead to higher repeatability, lower defect rates, and the ability to scale niche hydro dipping patterns beyond custom runs, democratizing advanced hydrographic capabilities.

Key Applications of Trending Hydro Dip Patterns

Trending hydro dipping patterns in 2025 find diverse applications across automotive, defense, outdoor gear, electronics, fashion, and home décor. Each sector requires tailored process control and specific finishing techniques. Automotive and outdoor applications demand high-durability clear coats and abrasion resistance. Electronics and fashion prioritize visual fidelity and surface texture. Understanding application-specific finishing and testing ensures hydro dipping patterns perform reliably under expected conditions.

Tactical Patterns in Outdoor Gear

In 2025, military and tactical hydro dipping patterns serve functional camouflage and lifestyle aesthetics in defense and outdoor gear. Functional applications prioritize abrasion resistance and matte finishes to avoid glare. Chemical compatibility with durable coatings is critical. Performance testing includes abrasion, UV exposure, and adhesion tests. Ethical and regulatory considerations influence procurement. Use matte or low-gloss clear coats and films rated for impact/abrasion resistance for optimal concealment and durability.

Carbon Fiber & Textures in Automotive

Chrome carbon and realistic textures deliver perceived luxury in automotive customization, mimicking high-end materials without the cost or weight. Popular for dashboard trims, center consoles, and wheel accents. Achieving durability requires multi-stage clear coats with UV stabilization and flexible hardness profiles to withstand temperature cycling and mechanical stress.

Thorough degreasing, adhesion promotion, and correct base-coat color are critical for a flawless finish. These textures increase perceived vehicle value and offer a cost-effective route for prototype testing, beneficial for concept and show vehicles.

Abstract Patterns in Electronics & Décor

Modern and abstract hydro dipping patterns create distinct, personalized consumer goods like phone shells, jewelry hardware, and accent home décor. These applications demand high-resolution prints and careful scale matching for intricate motifs on small, irregular surfaces. Durability varies: phone cases need scratch resistance and flexible clear coats; home décor prioritizes UV resistance and gloss control. Pattern scaling is critical, often requiring custom repeats for perfect proportion on unique objects.

Test clear coat adhesion on representative substrates for long-lasting results. Graded scratch tests help select appropriate top coats that protect aesthetic details without altering texture or visual appeal.

Hydro Dipping Market Trends & Future Outlook 2025

The hydrographic film market in 2025 is expanding due to customization demand across automotive, consumer electronics, and lifestyle products. Growth is fueled by improved film printing, sustainable practices, and automation enabling small-batch repeatability. Market indicators show steady interest from DIY enthusiasts and commercial shops adopting advanced tooling. Geographic hotspots mirror strong automotive and manufacturing clusters.

Both individual buyers and small businesses should anticipate continued opportunities but also increasing competition as high-fidelity films and automation become widespread. Watch for AI-assisted mapping and biodegradable film chemistries as near-term disruptors, influencing cost structures and expanding product offerings.

Conclusion

As we navigate 2025, Hydro Dipping Patterns continues its dynamic evolution, driven by advancements in pattern complexity, sustainability, and automation. From the rugged utility of E3D tactical geometries and the luxurious appeal of chrome carbon fiber, to the expressive artistry of modern abstracts and the exclusivity of niche designs, the range of trending hydro dipping patterns offers unparalleled customization.

Success in this evolving landscape hinges on meticulous technique, strategic sourcing of high-quality, eco-friendly materials, and embracing technological innovations. With diverse applications spanning automotive, outdoor gear, electronics, and home décor, the hydrographic market is poised for sustained growth, offering exciting opportunities for hobbyists and professionals alike to transform ordinary objects into personalized masterpieces. you can read our comparison guide about Hydro Dipping: Essential Materials for Beginners also.