Hydro Dipping Metal vs Plastic: Real 2025 Results

Hydrographic dipping film has reshaped the scene of customizing everyday objects with intricate designs and patterns. More than 2000 types of custom-designed films exist globally, and this versatile technique transforms everything from automotive parts to household items. The simple concept applies to any material that can withstand water submersion, which makes this process adaptable for hobbyists and professionals alike.

Materials respond differently to water transfer printing hydrographics. Metal, plastic, wood, glass, ceramics, and fiberglass rank among the most popular Hydro Dipping Metal vs Plastic materials in projects. This process stands as a perfect example of form meeting function. The technique enables detailed customization in a variety of objects, though costs run 5 to 10 times higher than average powder coating. Hydrographic water transfer film, which creates large-area pattern effects, yields distinct results on Hydro Dipping Metal vs Plastic versus plastic surfaces.

Let’s take a closer look at how Hydro Dipping Metal vs Plastic performs on Hydro Dipping Metal vs Plastic versus plastic surfaces to help you achieve the best results for your next customization project. The guide covers everything from surface preparation to long-term durability for these two popular substrate materials.

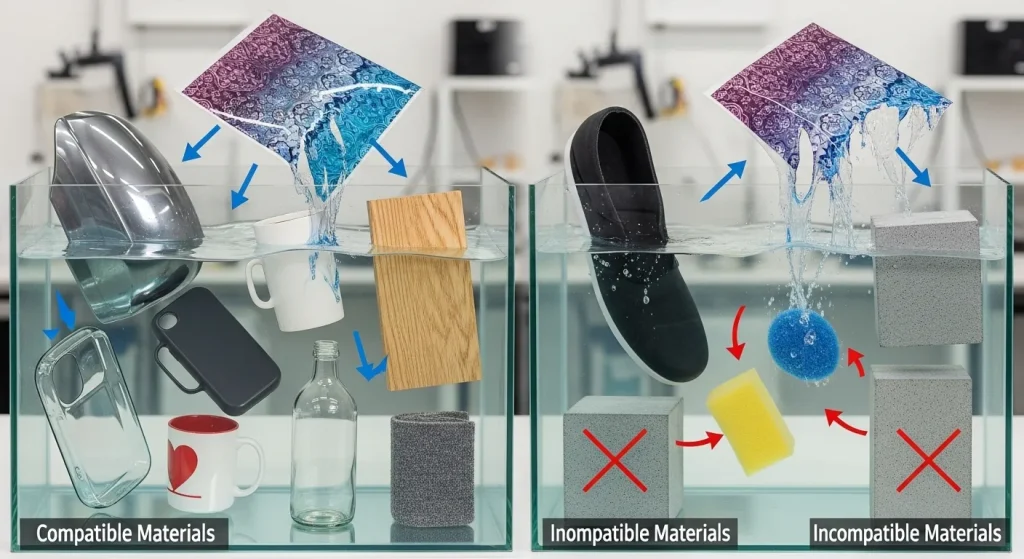

Material Compatibility with Hydrographic Film

Success in hydrographic dipping starts with knowing how different materials work with the process. Water transfer printing hydrographics needs specific attention to your substrate material, unlike regular painting.

Surface Preparation: Hydro Dipping Metal vs Plastic

The difference between professional results and amateur attempts comes down to substrate preparation. Both Hydro Dipping Metal vs Plastic need thorough cleaning to remove contaminants, dirt, oils, wax, grease, and loose paint that could ruin the finished product.

Metal surfaces need sanding with a Scotch-Brite pad to create a slightly textured profile that helps paint stick better. Plastic surfaces need special treatment based on what they’re made of:

- Standard plastics (ABS, PVC): These usually take Hydro Dipping Metal vs Plastic with basic prep

- HDPE plastic: You’ll need to treat it with flame before starting

- Other plastics (PP, PET, EVA): These need testing to make sure they’ll hold properly

Adhesion Properties: Porous vs Non-Porous Surfaces

The base coat is a vital bonding agent between your substrate and other layers in the paint system when applying hydrographic film. Non-porous surfaces like plastic create unique challenges because of their basic properties. Water-based applications don’t work well with non-porous substrates because they don’t wet properly, this happens due to surface tension differences. Non-porous polyethylene films have a surface energy of 28–32 mN/m, while water’s surface energy sits much higher at 73 mN/m. Metal surfaces take hydrographic film better after proper priming, even though they’re non-porous too. They provide better mechanical adhesion once you rough up their surface slightly.

Primer and Base Coat Requirements for Each Material

Your substrate material determines which primer and base coat you should use. Urethane primers work great on properly prepped metal, wood, and fiberglass surfaces. They build up well, sand easily, and stick properly. Bare steel and other metals need epoxy primers to stop rust and corrosion while helping things stick better.

These primers stay flexible enough to handle surfaces that expand and contract as temperatures change. Plastic needs special attention when it comes to base coat compatibility. Most professionals use automotive-grade urethane-based paints because they handle activator exposure well. On top of that, your base coat’s color makes a big difference in how things look at the end since it shows through parts of the hydrographic film pattern. Stay away from single-stage oil-based acrylic enamels. These paints dry from outside to inside, stay soft in the middle, and cause problems with hydrographic film adhesion.

Hydro Dipping Process Differences

Metal and plastic substrates show key differences in the Hydro Dipping Metal vs Plastic process. These differences change how materials behave during immersion and affect their final curing needs.

Water Absorption: How Hydro Dipping Metal vs Plastic Behave in Water

Metal and plastic react differently to water during dipping. Plastic doesn’t absorb water because it’s non-porous, which makes it perfect for hydrographic dipping film application. The film sticks better to the surface since moisture can’t seep in. Metal also works well as a non-porous material but needs extra care to stop rust or corrosion while it’s in water.

Activator Sensitivity: Film Reaction on Different Surfaces

The activator plays a vital role in melting the ink on hydrographic water transfer film, and it reacts differently with each material. Too little activator stops the film from sticking properly, while too much makes the ink spread out and won’t stick to the surface. You’ll get the best results when:

- Metal surfaces need exact activator amounts since the chemical reaction happens faster on them

- Plastic surfaces, especially ABS, work better with activator and give you more time to apply it right

The activator’s ingredients (xylene, isobutanol, butyl, methyl acetate, and methyl ethyl ketone) must match the material type to melt the film properly.

Drying and Curing Time: Hydro Dipping Metal vs Plastic

Each material needs different drying and curing times. Thermoplastic and non-metal products need drying temperatures under 60°C, but Hydro Dipping Metal vs Plastic products can handle up to 180°C after washing. The top coating cure temperatures also vary – plastic parts need 65°C for 45 minutes, while metal needs 120°C for 60 minutes. These differences come from each material’s heat tolerance and physical properties that affect production schedules and equipment needs for water transfer printing hydrographics projects.

Visual and Pattern Results

Base material plays a crucial role in determining how hydrographic film looks after application. The way base coat, substrate properties, and film interact creates unique results when comparing Hydro Dipping Metal vs Plastic surfaces.

Color Vibrancy: Hydro Dipping Metal vs Plastic Outcomes

Base coat color substantially influences the final look of hydrographic dipping projects. Hydrographic films have some degree of translucency that lets the base coat affect color intensity. Colors appear more vibrant on plastic surfaces and stay true to the original film design because non-porous surfaces create a smooth backdrop for the ink. Hydro Dipping Metal vs Plastic surfaces need specific base coat colors to achieve similar vibrancy. White base coat creates the brightest and most vivid results on both materials. This makes patterns stand out just like they do in product catalogs. Base coat selection can change the film’s appearance completely, especially with specialized applications like carbon fiber patterns.

Pattern Stretching and Warping on Curved Surfaces

Water transfer printing hydrographics face unique challenges on curved surfaces. Poor technique leads to distorted, fuzzy patterns when film stretches on contoured parts. Pattern integrity stays intact when you cut enough film and dip at a 45° angle. Materials respond differently to this process. Pattern distortion happens more around complex curves with plastic components due to their flexibility. Experts note that “Overhangs, interior corners, and regions of deep concavity will be missed by the draping film”. These pattern-free zones appear whatever the material type.

Texture and Finish: Matte vs Glossy on Each Material

Items get a clear coat finish in gloss, flat, or matte after hydro dipping. These automotive-grade clear coats protect the surface and determine its final appearance. Glossy finishes on metal tend to highlight patterns with better definition, while matte finishes create subtle effects.

Hydrographic Water Transfer Film Behavior by Material Type

Hydrographic water transfer film interacts differently with various materials. Hard plastics provide smooth, non-porous surfaces that create strong adhesion and sharp patterns. Metals need more preparation to match these results. Chemical components in the activator create proper bonding by softening the base coat. Success comes from understanding each material’s specific needs rather than using generic approaches.

Durability and Real-World Performance

Quality hydrographic dipping shows its true value through ground performance after installation. Your customized item’s durability factors determine whether it stays vibrant and intact or deteriorates too soon.

Scratch Resistance: Coated Metal vs Coated Plastic

Metal and plastic hydro dipped items get substantial protection from their final clear coat application. Quality clear coats make hydro dipped finishes resistant to abrasion, chemicals, and UV damage, unlike standard vinyl that peels or fades with time. Notwithstanding that, scratch resistance depends on the substrate material:

- Metal surfaces become harder after curing

- Plastic items stay more vulnerable to deep scratches

The finish type plays a crucial role in durability. Automotive-grade clear coats offer standard protection, while ceramic-based alternatives like Cerakote deliver better abrasion resistance. On top of that, it takes 30-90 days to fully cure, and durability keeps improving during this time.

UV and Weather Resistance Comparison

Environmental factors create tough challenges for hydro dipped items. High-quality Hydro Dipping Metal vs Plastic films with proper UV inhibitors resist fading and color degradation even under long sun exposure. The best weather resistance comes from:

- Quality films with UV-resistant properties

- UV-inhibiting clear coats as protective layers

- Proper maintenance to avoid quick deterioration

Metal items usually have better weather resistance because they stay dimensionally stable during temperature changes, while plastic expands and contracts more dramatically.

Long-Term Adhesion: Which Material Holds Better Over Time

Hydrographic film’s typical lifespan on an item ranges from five to fifteen years. Metal surfaces need more preparation but deliver better long-term adhesion than plastic. Decorative pieces last longer than frequently handled objects. Poor surface cleaning before application causes most early film failures on both materials. Both substrates need high-quality primers, topcoats, and professional application techniques to last longer. Hydro Dipping Metal vs Plastic performs better than plastic in extreme conditions thanks to its natural structural stability.

Conclusion

Hydro Dipping Metal vs Plastic transforms both metal and plastic with stunning custom designs, though each needs its own prep. Metal requires roughening for adhesion, while plastic, especially HDPE, needs chemical treatment. The base coat color matters since films are transparent; white bases give the boldest colors.

During dipping, metal reacts faster to activators, while plastic allows more working time. Drying differs too, plastic cures best around 65°C, metal up to 120°C. Metal wins slightly on durability, resisting scratches and holding designs longer. Plastic can scratch easier but still shines with proper prep and coating. you can read our Hydro dipping guide about Customizing Your Car Parts with Hydro Dipping also.

Choose based on your project: metal suits outdoor and long-term use; plastic is easier to handle and often shows patterns more vividly. With careful prep, good films, and pro clear coats, both materials deliver lasting hydrographic results.