How to Choose the Right Hydro Dipping Tank Size

Let me tell you about hydro dipping. The sort of thing I love about it is how it transfers complex patterns like camo or wood grain onto three-dimensional objects. This technique, also called water transfer printing or hydrographic printing, will give you vivid colors and complete coverage with your chosen pattern.

The process works in a surprisingly simple way. Paint floats on water’s surface and transfers to objects during dipping. This creates psychedelic effects that never repeat twice. The beauty of hydro painting lies in its versatility – it works with any material that can handle water submersion. Ceramics, plastics, metal, and fiberglass all take beautifully to the process. Many enthusiasts start their journey with spray paint as their first attempt at this adaptable technique.

Professional results need the right equipment, especially for bigger projects. A high-quality hydro dipping Tank Size becomes essential to achieve superior outcomes. Your Tank Size determines the projects you can handle and your work’s efficiency.

This piece covers everything about picking the perfect hydro dipping tank size for large-scale projects. We’ll help you learn about the basics and specific requirements for different materials. Our professional insights will lift your hydro dipping skills to new heights.

Understanding Hydro Dipping and Tank Size Roles

A hydro dipping tank is the life-blood of every successful water transfer printing operation. This specialized container maintains water at exactly 90°F (32°C). The precise temperature creates perfect conditions that allow PVA film to soften and stick well to your project.

Key Features of Quality Tanks

Quality tanks do nowhere near just hold water. Professional models come equipped with temperature controls, industrial heaters, pumps, and film-divider systems. These features work together to maintain optimal conditions throughout your dipping session and deliver consistent results.

Tank Materials and Sizes

Manufacturers build tanks using stainless steel, aluminum, or plastic. Stainless steel stands out as the most durable and long-lasting choice for serious projects. Your tank’s size will determine what you can dip, from small phone cases to larger items like car dashboards or ATV parts.

The Film Hydration Process

The right tank setup plays a crucial role in how hydrographic film hydrates before activation. Your film needs to rest on the water’s surface for 60–75 seconds before you apply an activator that dissolves it into a fluid state. The water’s surface tension helps the pattern curve naturally around complex shapes when dipping starts.

The Final Rinse and Finish

A quality tank system helps rinse away leftover PVA material after dipping. This final step improves your hydro dipped items’ appearance and durability by a lot.

Key Factors That Influence Tank Size

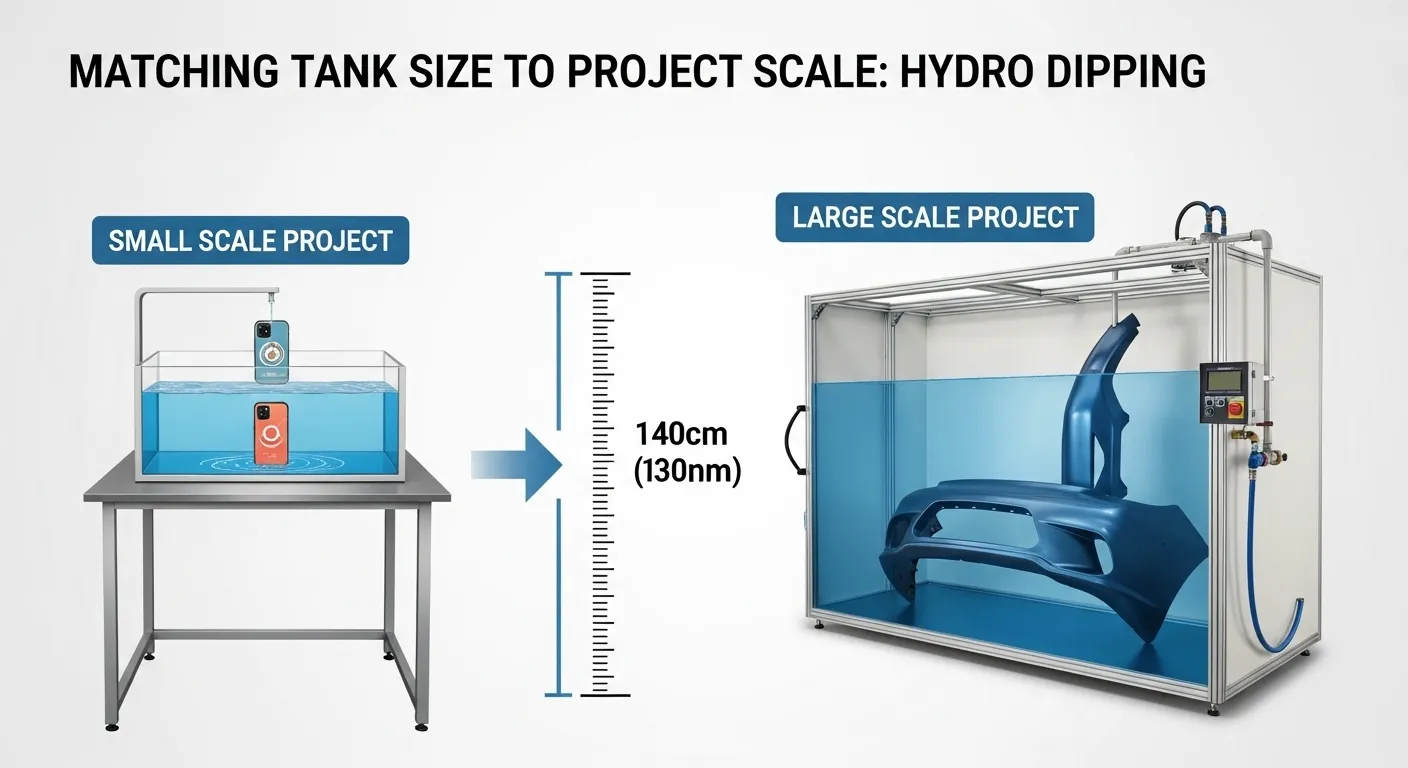

The right hydro dipping tank size depends on a few key factors. Your dipping items’ dimensions play a crucial role in this decision. A 1.2-meter entry-level tank works well for smaller objects like rifle stocks, hard hats, and rims up to 20 inches. Professional tanks with 34-inch dipping areas can handle bigger items such as motorcycle gas tanks and 30-inch rims.

Choosing the Right Size for Your Projects

Larger production-level tanks (2.8-meter) are needed for ATV bodies, golf cart parts, and full car dashboards. Your production volume also shapes this choice, hobby operations work fine with 3–5 ft length tanks, while industrial facilities need systems that are 12 ft or longer.

Understanding Technical Specifications

The tank’s technical specs need careful attention. Water temperature should stay between 25–35°C. Professional tanks come equipped with temperature controls, industrial heaters, high-efficiency circulation pumps, and filtration systems.

Evaluating Tank Materials and Durability

Tank materials make a big difference in how long they last and how well they perform. Entry-level tanks usually have fiberglass bodies with steel frames. Professional and production tanks are built with stainless steel, often 2–2.5 mm thick.

How to Choose the Right Tank Size for Your Needs

A full picture of your project scope helps you pick the right hydro dipping tank. Mini DIY tanks work well for beginners and hobbyists who work with small items like phone cases or gun components. Small business owners might want to think about standard 1.2-meter tanks that fit parts up to 20 inches. Also you can read our comparison guide about Hydro Dipping Without Activator.

Matching Tank Size to Project Scale

Businesses handling larger components need wider tanks with at least a 34-inch dipping area. Production-level 2.8-meter tanks are needed when you work on big projects like ATV bodies or golf carts.

Construction Quality and Durability

The tank’s construction matters a lot. Stainless steel tanks last longer and resist chemicals better. Quality tanks should have 2–2.5 mm thick stainless steel with proper welding that prevents leaks.

Essential Features and Specifications

Size isn’t everything in a hydro dipping tank. You need good temperature controls to keep water at 25–35°C, circulation pumps (375W for smaller tanks, 750W for larger models), and filtration systems to clean film residue. Modern tanks come with wipers and partition beams that keep film from spreading too much.

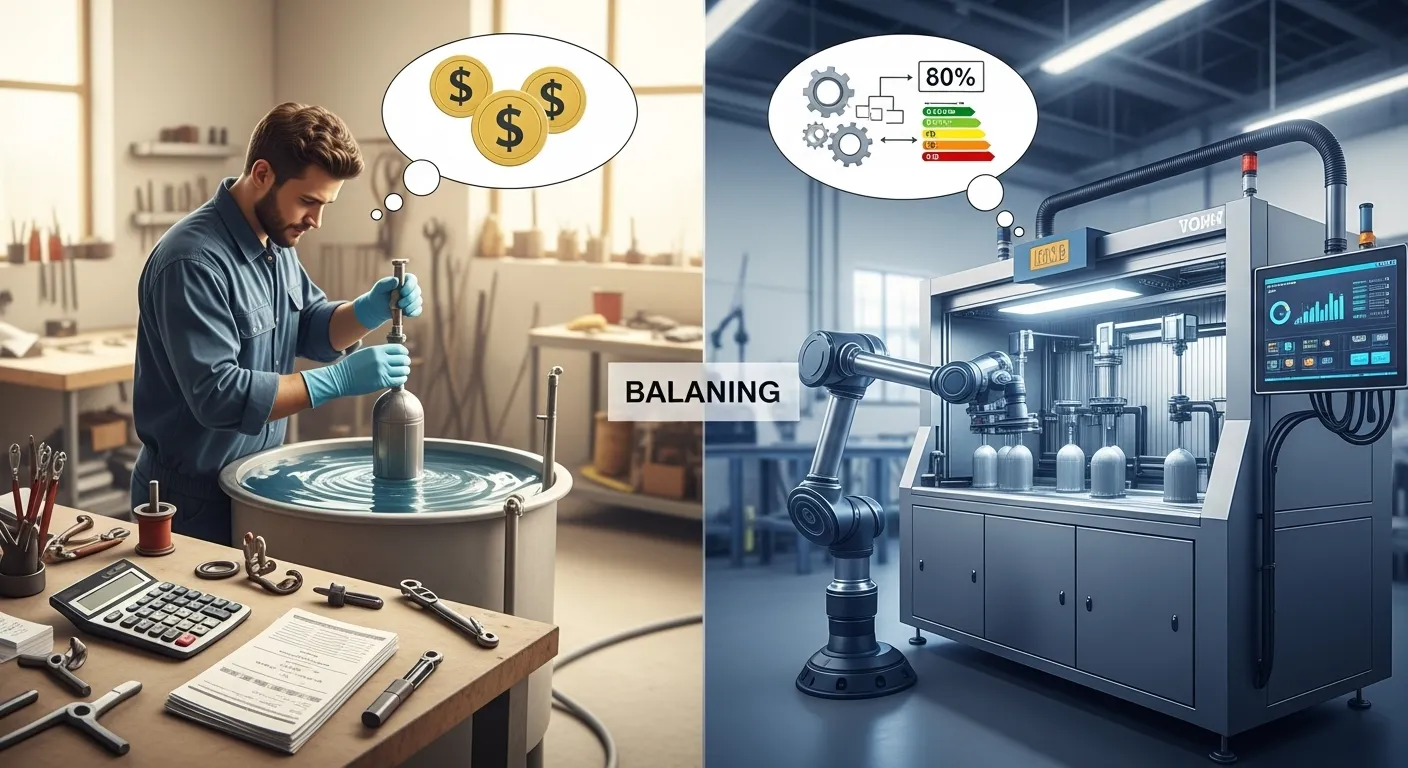

Balancing Budget and Automation

Your budget plays a big role in what you can get. Manual tanks cost nowhere near as much as semi-automatic or automatic systems. All the same, automatic systems with robotic dipping arms are a great way to optimize large-scale projects if your production volume makes sense.

Conclusion

Choosing the right hydro dipping tank is key to successful water transfer printing. Tank size determines what projects you can handle, from small parts to full ATV bodies. Stunning Marble Effects is also a good guiding.

Stainless steel tanks offer the best durability, while proper temperature control, circulation, and filtration ensure professional results.

Beginners can start with smaller tanks, upgrading as their workload grows. Consider your space, budget, and production needs before investing.

The right tank transforms ordinary objects into custom, professional-quality pieces built to last.