Hydro Dip Durability Test: Real Results After Years of Use

Many people wonder about the staying power of a Dip Durability Test finish. This question pops up a lot before someone decides to invest in this customization method. A well-applied and maintained hydrodip treatment can last 5 to 15 years. The durability might surprise you.

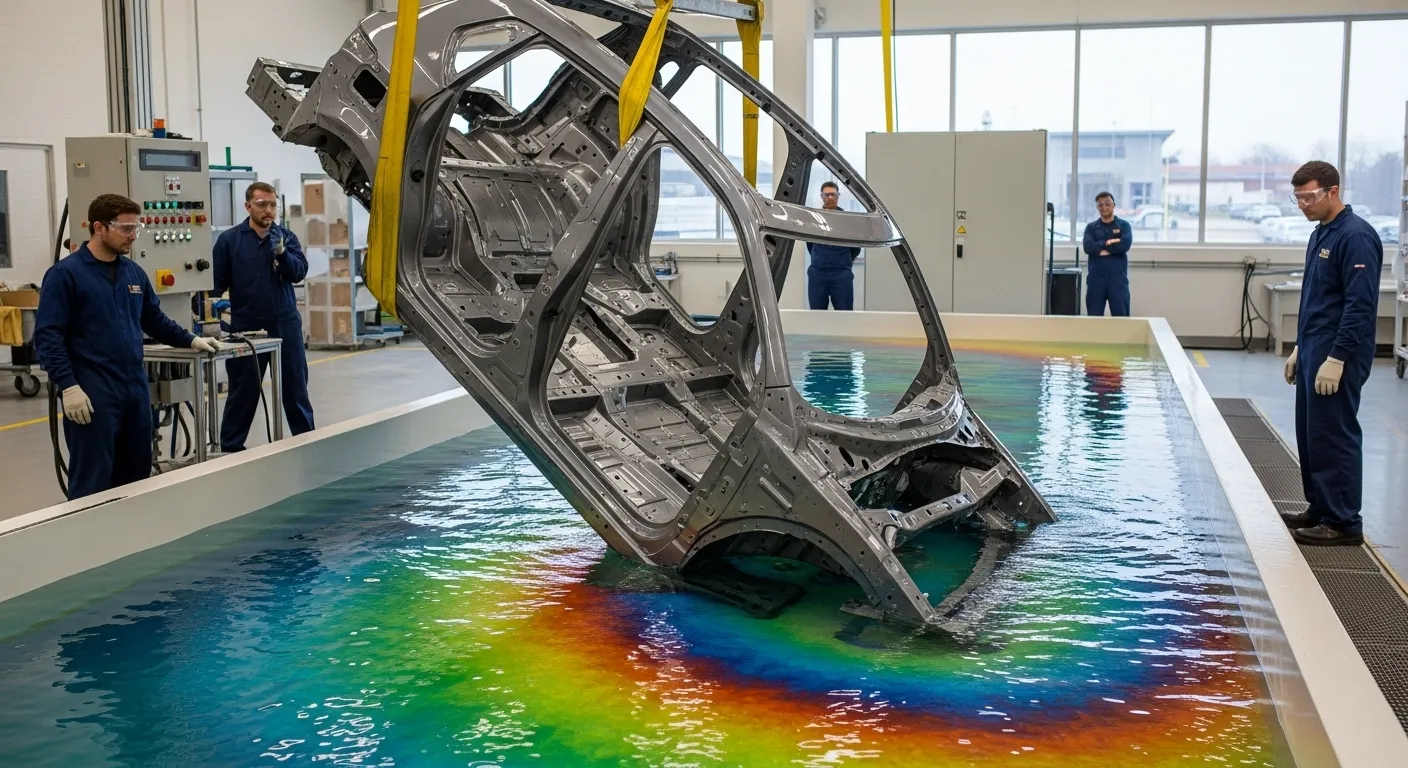

Water transfer printing, or hydro dipping as most people call it, has gained huge popularity. People use it to customize everything from car parts to home decorations. The lifespan of your hydrodip project depends on several things. Surface preparation and careful handling make a big difference. Poor handling stands out as the biggest reason why hydrodipped items wear off too soon.

Decorative pieces that don’t get much use tend to keep their looks much longer. . Hydro Dip Paint vs Spray Paint is vary good guiding.

This piece dives into ground test results of hydrodip durability. You’ll learn about the crucial factors that determine how long your finish lasts. We’ll share useful tips to help your hydro dipped creations stay beautiful longer. These insights will guide you toward lasting results, whether you’re using a DIY kit or going with professional services.

Key Factors That Influence Hydro Dip Durability

Your hydrodip finish can stay vibrant for years or fade within months depending on several key factors.

Surface Preparation

Surface preparation is the vital first step. Without proper cleaning, sanding, and priming, no finish will stick properly. Even the best materials can’t make up for poor surface prep.

Quality of Materials

The quality of materials you use throughout the process will affect how long your finish lasts. You’ll need high-quality primers, films, base coats, and most importantly, clear coats to get professional results. A reliable automotive-grade clear coat helps protect against UV damage, scratches, and chemical exposure. The clear coat’s thickness relates directly to durability, thicker layers give better protection.

Environmental Conditions

Environmental conditions during application matter more than you might think. Water temperature should be between 27°C–32°C, and the air temperature needs to stay around 20°C–25°C with humidity between 40%–60%. When these conditions aren’t right, you might see problems like poor adhesion, bubbling, or cracking.

Usage and Exposure

Usage patterns are the biggest factor in determining how long your finish will last. Items people handle often will show more wear than display pieces. Exposure to direct sunlight, extreme temperatures, or harsh chemicals will also reduce how long the finish lasts.

Longevity Expectations

A well-done hydrodip finish can look great for 5–15 years. Items kept outdoors need more frequent care than those used inside.

Hydro Dip Durability Test Results Over Time

Lab and real-life testing shows how hydrodip finishes hold up over time. Professional durability tests simulate friction, check chemical resistance, and expose samples to environmental conditions to predict real-life performance.

Temperature Resistance

These finishes show impressive temperature resistance. Properly cured hydrodip finishes stay stable between 0°F and 120°F without breaking down. Quality finishes can handle quick exposure to temperatures up to 325°F. This makes them perfect for automotive parts that heat up frequently.

Long-Term Performance Studies

The largest longitudinal study shows that hydrodipped items keep their looks for 5–15 years with proper sealing. Decorative pieces that people rarely touch last even longer. The finish gets tougher as the curing process continues for 30–90 days after application.

Real-Life Automotive Testing

Real-life tests on car wheels prove that hydrodip with automotive-grade UV-resistant clear coat lasts 3–5 years under normal use. The wheels without good clear coats start falling apart within six months because of UV rays and brake dust.

Lab Findings on Clear Coat Performance

Lab tests confirm that ceramic-infused clear coats resist scratches better. Premium automotive-grade clear coats maintain their strength up to 200°C (392°F). This prevents the typical breakdown that happens with standard finishes.

How to Extend the Life of Your Dip Durability Test Items

Your hydrodip customization investment needs regular maintenance and careful handling. The most crucial step starts right after the dipping process when you apply a high-quality clear coat. Automotive-grade clear coats with UV inhibitors protect your design from sun damage and provide scratch resistance. Items used outdoors frequently need specialized formulas like Nanochem UV-resistant clear coats that can handle extensive environmental exposure.

Proper Curing and Cleaning

Let your item cure fully (8–24 hours for simple use, 30–90 days to achieve maximum durability) before you start a regular cleaning schedule. Mild, pH-neutral soaps designed for automotive finishes work best. Harsh chemicals can damage the protective layers, so avoid them.

Maintenance Practices for Long-Lasting Results

These maintenance practices will give you the best protection:

- Apply a layer of high-quality carnauba wax every 2–3 months to create an extra protective barrier

- Keep items away from direct sunlight when possible

- Fix small damages quickly with matching paint or specialized touch-up pens

- Make sure items are completely dry before storage to avoid moisture damage

Handling and Longevity

Poor handling causes most premature hydrodip deterioration. Your hydrodipped items can look great for 5–15 years if you take good care of them, particularly those that don’t get handled much.

Conclusion

Hydrodipping is a highly durable customization method when done correctly. Proper surface preparation and premium clear coats can extend an item’s lifespan from around 5 years to over 15.

Environmental control during application, maintaining ideal temperature and humidity,prevents issues like bubbling or poor adhesion. Usage and handling also determine whether your finish stays flawless or needs early touch-ups. Also you can read our comparison guide about How to Choose Hydrographic Dipping Film.

Tests confirm the strong resilience of professional hydrodip finishes, especially when paired with UV-resistant and heat-tolerant clear coats. Even automotive parts exposed to high temperatures perform well over time.

Regular maintenance, including gentle cleaning and occasional waxing, is key to long-term durability. With proper care, hydrodipped items offer lasting visual appeal and impressive protection, making it a reliable choice for both aesthetics and performance.