Hydro Dipping Machines & Water Transfer Printing Experts

Hydro Dipping Machines, Films & Water Transfer Printing Experts

Hydro dipping, also known as water transfer printing, has transformed the way we think about design, customization, and surface finishing. From car parts and helmets to shoes, gaming gear, and industrial products, this innovative technology allows ordinary items to be turned into eye-catching works of art.

For more than a decade, our company has been at the forefront of hydro water transfer printing, offering high-quality hydro dipping machines, professional hydro dipping services, and a wide range of hydro dipping films and patterns. Whether you are a hobbyist, a business owner, or a large-scale manufacturer, hydrographics provides a fast, durable, and cost-effective way to add unique finishes to your products.

What Is Hydro Dip Painting (Water Transfer Hydrographics)?

Hydro dip painting, often called water transfer hydrographics, is a surface decoration process that applies printed designs to three-dimensional objects. Instead of using traditional spray painting, the design is printed on a specialized hydro dipping film that floats on the surface of the water. With the right chemicals and dipping technique, the film adheres smoothly to the object’s surface, creating a flawless finish.

This process, also known as water transfer painting, works on a wide variety of materials, including plastic, wood, metal, and glass. That’s why industries like automotive, fashion, and consumer electronics rely heavily on hydro dipping to achieve unique looks that can’t be replicated with ordinary paint.

How the Water Transfer Printing Process Works

The process of hydro dip painting may look magical, but it follows a simple step-by-step method:

- Preparation: The item is cleaned, primed, and sometimes base-coated with paint to ensure proper adhesion.

- Film Placement: A chosen hydro dipping film or design pattern is placed on the water’s surface.

- Activation: A special activator chemical is sprayed onto the film, turning it into a liquid ink.

- Dipping: The item is slowly dipped into the water, allowing the pattern to wrap around it seamlessly.

- Rinsing and Drying: Excess film is rinsed off, and the piece is dried.

- Clear Coating: Finally, a protective clear coat is applied for durability and shine.

Hydro dipping stands apart from paint dipping because it delivers intricate graphics, such as carbon fiber, camouflage, wood grain, or custom artwork, instead of just a solid color.

Hydro Dipping Machines and Equipment

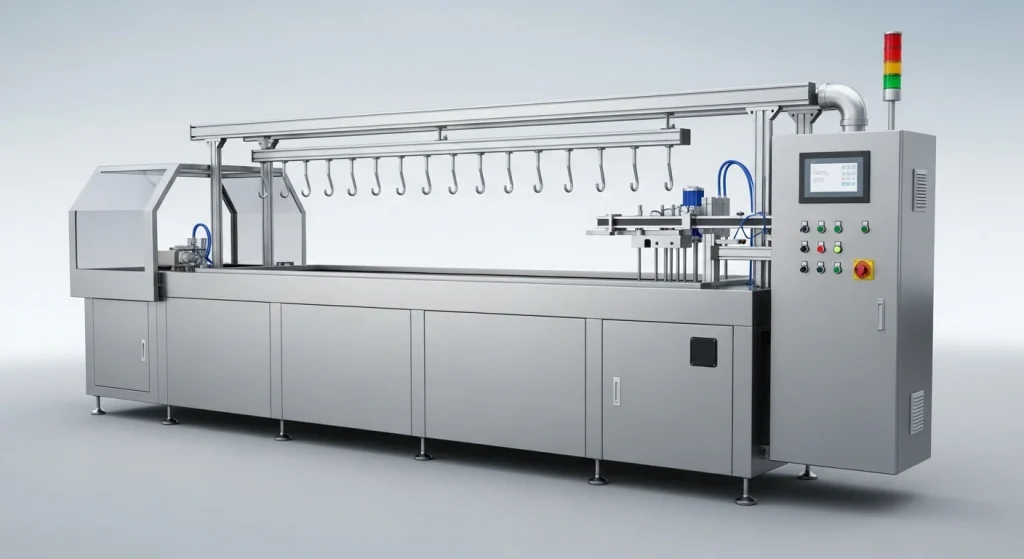

To achieve professional results, having the right hydro dipping equipment is essential. Our state-of-the-art systems are designed to make the process smooth, efficient, and repeatable.

Automatic Hydro Dipping Machine V5.0

The Fully Automatic Hydro Dipping Machine V5.0 is equipped with a smart temperature control system, automated activator spray mechanism, film feeding system, robotic dipping arm, continuous water circulation, and an automatic film dust filtration feature.

With a single touch, it effortlessly completes the entire hydro dipping process from start to finish.

Hydro Dipping Machine for Sale & Price Guide

If you’re looking for a hydro dipping machine for sale, we offer options for both small workshops and large-scale factories. The hydro dipping machine price depends on the size, automation level, and features, but we ensure competitive pricing without compromising on quality.

For beginners or small businesses, we also provide affordable hydro dipping kits and portable setups.

Hydro Dipping Patterns and Designs

One of the biggest attractions of hydrographics is the variety of hydro dipping patterns available. With over 20,000 hydro dipping designs to choose from, and 30+ new patterns added each month, there’s no limit to what you can create.

Some of the most popular options include:

Whether you’re decorating a small accessory or producing parts for mass distribution, custom hydrographic films make it possible to stand out in any market.

20,000+ Patterns

30+ New Patterns / Month

Fast Sample

Development Offer 7–10 Days

10+ Years

Manufacturing Experience

Custom Packaging

Tailored Shipping Solutions

Hydro Dipping Kits and DIY Options

Not every project requires industrial equipment. Our hydro dipping kits are perfect for individuals and small businesses looking to experiment or handle custom orders. These kits come with everything you need, including films, activators, and basic tools, making them an excellent entry point into the world of hydrographics.

Hydro Dipping Services We Provide

Alongside equipment, we are a full-service hydro dipping company offering customized hydro dipping services for clients worldwide.

Professional Hydro Dipping Service

Our UV curing setup handles both custom and bulk production with ease. Whether it’s one custom helmet or thousands of parts, we deliver fast, consistent, and high-quality finishes every time.

Custom Paint Dipping

We also provide paint dipping and water transfer painting services for brands seeking unique finishes. This includes applying durable coatings with advanced designs that elevate the look and value of products.

Bulk & Industrial Water Transfer Printing

From sporting goods to industrial components, our hydro dipping service is scalable for any project size.

20,000+ Hydro Dipping Patterns for Your Business

Hydro Dipped Shoes

Hydro Dipped Skooty

Gun Toy

Hydro Dipped Hat

Hydro Dipped Cap

Industries Using Hydro Dipping and Hydrographics

Hydrographics are widely used across industries, including:

This versatility makes hydro dipping one of the most practical finishing solutions for both creative and commercial purposes.

Hydro Dipping Services

Our state-of-the-art Water Transfer Printing and Hydro Dipping facility is equipped to handle everything from individual custom items to large-scale production runs and bulk manufacturing projects.

Chrome Plating & UV Curing

Our Chrome Plating facility features a fully enclosed, dust-free paint booth equipped with high-precision automatic spray guns (20ku/h), ensuring a flawless finish with exceptional efficiency.

Free Training & Consultation

As a trusted name in hydro dipping, HYDRODIPPING offers comprehensive training in our dedicated training center. We provide hands-on guidance and expert consultation for all aspects of the hydro dipping process—from basic techniques to advanced production workflows.

Get Started with Hydro Dipping Machines and Services Today

Hydro dipping has revolutionized how businesses and individuals customize products. With endless hydro dipping patterns, advanced hydro dipping machines, and professional services, you can take your products to the next level.

Ready to start? Contact Hydro Dipping® today to explore our hydro dipping equipment for sale, request pricing, or book our water transfer printing services. Let’s fuel innovation together.